Admixtures: They’ve become an essential component for nearly every producer worldwide. In fact, the global concrete admixtures market grew from $14.79 billion in 2022 to $15.68 billion in 2023 at a compound annual growth rate (CAGR) of 6.0% (source: Concrete Admixtures Global Market Report 2023).

Concrete producers use admixtures primarily to 1) reduce the cost of concrete construction, 2) modify the properties of fresh and hardened concrete, 3) ensure the quality of concrete during mixing, transporting, placing and curing, 4) overcome certain emergencies during concrete operations, and 5) unlock material efficiencies for sustainability purposes.

Admixtures are classified in ASTM C494 (Standard Specification for Chemical Admixtures for Concrete) according to their function: water reducers, air entrainers, retarders, accelerators, corrosion inhibitors, shrinkage reducers, alkali-silica reactivity reducers, bond enhancers, etc. Each type has different chemistries that react differently once mixed with fresh concrete.

Given their essential role in concrete production, producers need to know how they work together, and with CarbonCure Technologies, before making any changes.

Does CarbonCure interact with any other cement-reducing admixtures?

CarbonCure's Research team has tested a range of the most common chemical admixtures in our own lab, and we have not identified any negative interaction with these chemical admixtures. And with hundreds of systems installed and operating at concrete plants around the world, we have not received any reports from customers about issues with CarbonCure and their admixture designs. CarbonCure Ready Mix technology is approved as a Type S (Special Performance) admixture within ASTM C494.

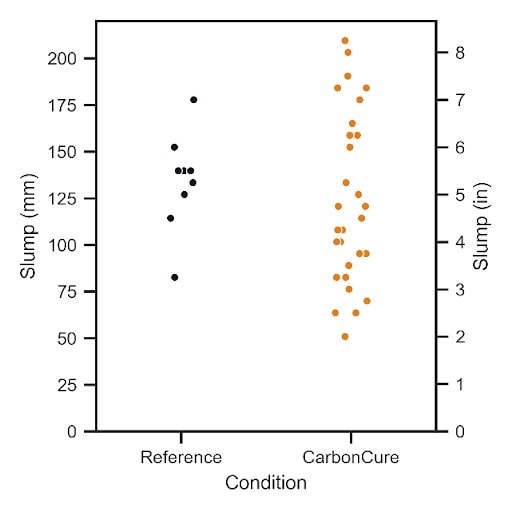

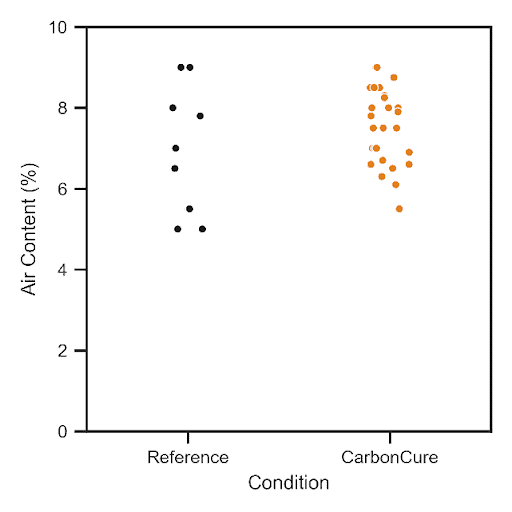

Figure 1 below shows dataset comparisons of field concrete mixes with and without CO2 that also contain air entrainers and water reducers. Performance is similar when comparing CarbonCure to the reference concrete mix.

Figure 1. Field data of concrete mixes containing air entrainer and water reducer. Air content and slump are comparable between the reference and CarbonCure mixes.

Is CarbonCure more effective than conventional water-reducing admixtures that serve to also lower the total cement content?

Including CarbonCure Ready Mix technology improves the cement efficiency of concrete (i.e., strength-to-cement content ratio). It does so by forming nano-sized calcite particles that catalyze hydration through the formation of a mixed carbonate-calcium-silicate hydrate product [1]. In other words, more hydration occurs per unit of cement.

CarbonCure's technologies are stackable. That is, our ready mix system works in combination with our reclaimed water system to increase carbon savings. In addition, CarbonCure's technologies can be stacked with non-CarbonCure materials or methods, including admixtures, to further reduce the carbon footprint of concrete. Our sophisticated concrete lab protocol paired with mix optimization help you put every component of your mix together to optimize cement and maximize efficiencies.

We’re here to help. Contact us with any questions.

References

1. Monkman, S., Kenward, P. A., Dipple, G., MacDonald, M., & Raudsepp, M. (2018). Activation of cement hydration with carbon dioxide. Journal of Sustainable Cement-Based Materials, 7, 160-181. doi:10.1080/21650373.2018.1443854.