On February 9, 2021, more than 240 people logged onto a highly interactive webinar about CarbonCure featuring CarbonCure’s Shannon Seipel, Technical Services Manager and Christie Gamble, Senior Director of Sustainability, titled “Everything You Wanted to Know About CarbonCure But Were Afraid to Ask.”

The webinar began with an overview of CarbonCure’s solution, breaking down how the technology works, followed by an overview on the installation process.

Next came a deep dive into how CarbonCure's Technical Services and Support (TSS) team works with Quality Control teams on commissioning trials, mix optimization, data testing and analysis, and mix design submittals. In addition, they delved into how the Market Development team provides all producers with sales and marketing training, marketing collateral, spec language and lead sharing to maximize new business opportunities.

With the technical overview complete, participants were asked to send in questions. With 96 total questions submitted, Shannon and Christie began their rapid-fire responses.

We invite you to learn more by reviewing these three questions that were submitted by numerous attendees and view the resources at the end of the blog. Thanks to all that attended and tried to stump our experts!

Watch the On-Demand Webinar with Shannon and Christie

Question 1: Will it work with my materials? Can CarbonCure be used with OPC, GUL, SCMs, various admixtures and aggregates?

Answer: More than 8 million cubic yards of concrete has been made with CarbonCure in a wide range of climates and conditions, ranging from Hawaiian summers to Canadian winters. This has resulted in CarbonCure being tested and used with a vast range of materials, including different types of cements, aggregates and admixtures.

To date, we have not found a material that is incompatible with CarbonCure. Like all things concrete, we do see variability in results. For example, some cements are more reactive with CO₂ and are able to provide higher mix optimization potential than others.

Of the 8 million+ cubic yards of concrete, CarbonCure has been successfully used with Type I and Type II portland cements, slag, fly ash (C and F), GUL (Portland Limestone cements), and ternary blends.

Many of CarbonCure’s concrete producer partners have declared that CarbonCure is compatible with all mixes and admixtures provided by their company. This includes superplasticizers, water reducers, freeze guards, water mitigators, air entrainment, etc.

CarbonCure concrete producer partners who wish to test compatibility and performance of CarbonCure on specific mixes or materials may contact their local Technical Services Representative for support.

Question 2: How do you calculate the carbon savings?

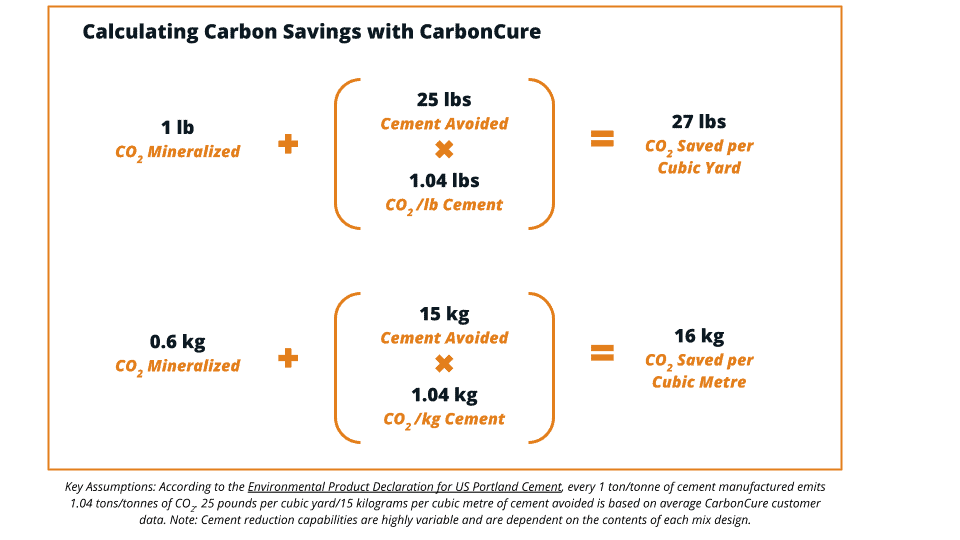

Answer: CarbonCure saves carbon through two methods:

- CO₂ mineralization; and

- Cementitious optimization.

First, a bit of background on what’s happening. CarbonCure introduces CO₂ captured from industrial emitters into the concrete mix. This is CO₂ that would otherwise be pollution released into the atmosphere. Once injected into the concrete mix, a chemical reaction occurs between the cement and CO₂ where the CO₂ mineralizes, becoming permanently embedded in the concrete.

This mineralization process protects the baseline design's strength, enabling concrete producers to optimize their mix designs and reduce cement content—without sacrificing strength. According to the Environmental Product Declaration for US Portland Cement, every ton/tonne of cement manufactured results in an average of 1.04 tons/tonnes of CO₂ produced. Therefore one of the best methods to reduce the carbon footprint of concrete is to reduce the amount of cement in the mix (while ensuring concrete performance is achieved).

On average, CarbonCure introduces 1 pound of CO₂ per cubic yard (0.6 kilogram per cubic metre) of concrete. The cement reduction enabled by that CO₂ varies substantially across various mix designs. CarbonCure typically enables a 25 pound cement reduction per cubic yard (15 kilogram cement reduction per cubic metre), while maintaining historical strength.

In the above example, the carbon savings per cubic yard of concrete would be calculated as:

CarbonCure may calculate an exact carbon savings for any given project, complying with industry-accepted Life Cycle Assessment methodology.

Question 3: My market is prescriptive, so how can I use CarbonCure where I have minimum cement and maximum water/cement?

Answer: Perhaps one of the most common misperceptions we see within the concrete industry is the belief that prescriptive specs can’t be changed.

The most common barrier that CarbonCure faces in commercial and public work are prescriptive specifications, including a required minimum cementitious content and maximum water/cementitious ratio. Conversely, performance specs require certain performance criteria be met (such as strength), without putting restrictions on how the concrete is made.

These specs can inadvertently inhibit the use of CarbonCure because they may not allow for a reduction in the cement content of a mix. As demonstrated by the carbon savings calculation above, the majority of carbon savings comes from being able to leverage the strength benefit of CO₂ to reduce cementitious content. If cement is not reduced, the carbon savings are minimal. Furthermore, concrete producers rely on the ability to reduce material costs to offset the costs of the CO₂ and CarbonCure.

Thankfully, the structural engineering community and National Ready Mix Concrete Association (NRMCA) are aligned on a mission to remove unnecessary prescriptive specifications in favour of performance-based specifications. This has been demonstrated to not only provide improved concrete sustainability, but also often results in better quality concrete.

The NRMCA’s Specification in Practice campaign contains substantial resources that validate the performance-based spec approach. Similarly, Structural Engineers 2050 is a movement of structural engineers who seek to eliminate embodied carbon by the year 2050. The organization provides justification and resources for engineers to adopt performance-based specs.

In the majority of circumstances, when structural engineers are given the opportunity to understand CarbonCure, review the material and review the data, they feel confident approving the recommended mix provided by the concrete producer.

Long story short, prescriptive specs are a challenge we face, but we’ve seen incredible success addressing this challenge head on and we encourage every concrete producer to work with us to eliminate these unnecessary barriers within their market.

To learn more about CarbonCure, we encourage you to visit our Resource Library. To get you started, here are a few recommended resources:

- Introduction to CarbonCure for Producers

- CarbonCure Information Package for Designers and Builders

- CarbonCure Explainer Video for Producers

- CarbonCure Producer Success Stories

If you are a concrete producer interested in implementing CarbonCure, please get in touch with a CarbonCure representative or call our toll-free number at +1 (844) 407-0032.

Razing a Common Misunderstanding: Early-Age Carbonation vs. Atmospheric Carbonation in Concrete