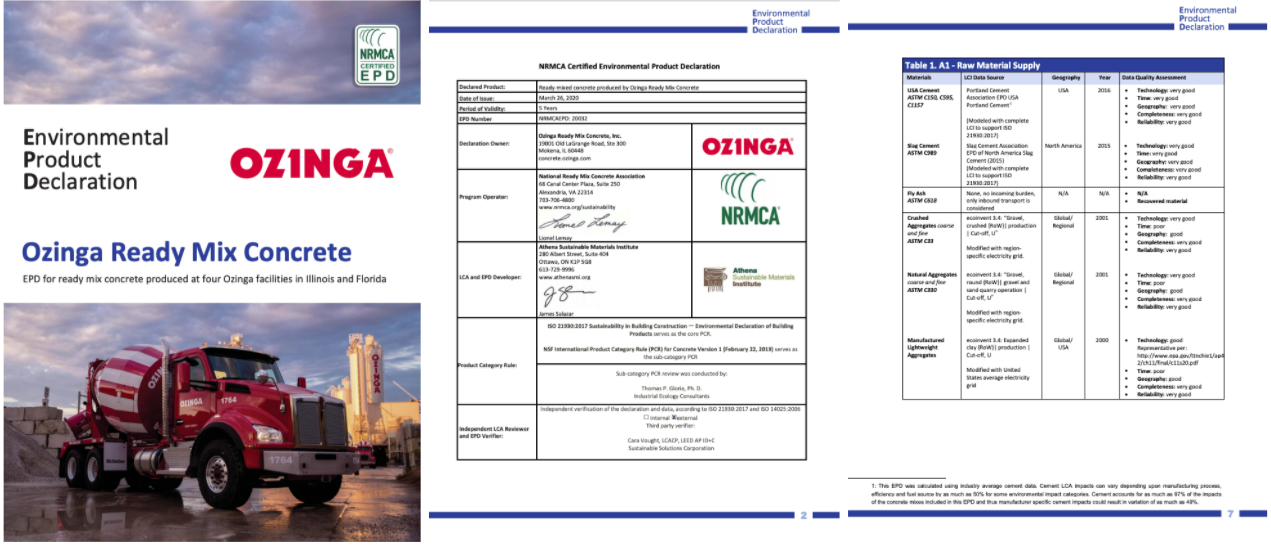

An Environmental Product Declaration (EPD) is an independently verified document, defined by the International Organization for Standardization (ISO) 14025 as a declaration that "quantifies environmental information on the lifecycle of a product to enable comparisons between products fulfilling the same function."

In the same way that nutritional labels report the measured nutrition facts for food products, EPDs report the measured lifecycle environmental impact of a product so designers and builders can make more informed decisions.

Companies implement EPDs to improve their sustainability goals and to demonstrate a commitment to the environment to customers. However, the green building market is starting to demand EPDs across a wide spectrum of building products—especially concrete products.

1. Industry & Governments Are Driving Change

It is expected that EPDs will become a requirement in many municipalities as new tools in the hands of policymakers are creating renewed interest in the carbon footprint of concrete. Research studies and initiatives by the design community—Architecture 2030, Thornton Tomasetti, Skanska, and so on—are highlighting the impact that building materials have on climate change.

And governments are already taking note: within the past year, procurement policies and legislation targeting low-carbon concrete have been introduced in Portland, Marin County, Hawaii, Austin, and New York State.

Today, LEED v4, Architecture 2030 Challenge for Products, and the International Green Construction Code are just some of the industry and regulatory bodies requesting that building product manufacturers submit EPDs to demonstrate the environmental performance of their products.

2. Proactive Adoption by Producers is Required

As the most abundant man-made material on the planet—and the most carbon-intensive—concrete is a big focus in the green building space. The industry has been proactive in taking measures to reduce the carbon footprint of their products. For example, supplementary cementitious materials (SCMs) like fly ash have been used for many years to reduce the cementitious content in concrete. However, due to the reduction in coal mines, fly ash is harder to source. The industry is now looking at carbon capture and utilization methods to continue to reduce its carbon footprint.

Now the focus is turning to transparency as producers adopt Environmental Product Declarations (EPDs) for their concrete mixes.

Lifecycle assessment (LCA) databases like OneClick and Embodied Carbon in Construction Calculator (EC3) include over 24,000 concrete EPDs available for products manufactured in the USA and Canada. The EPDs are searchable and sortable by strength, location, manufacturer, plant, mix ID, and so on and most are concrete mix and batching plant-specific. EPD searches may also be conducted on unique properties such as “CO2 Cured” concrete (in which concrete mixes made with CarbonCure’s CO2 mineralization technology apply).

EC3 is a free, open-access tool that allows designers and builders to review embodied carbon data prior to making design decisions. The tool sources information from published EPDs so, as long as producers publish a product-specific EPD, it will show up in EC3 for consideration by new and existing clients.

Concrete producers are encouraged to publish EPDs and to submit them on the EC3 website in order to grow the EC3 database, and help future project teams reduce embodied carbon.

3. Understanding EPDs

EPDs report on seven core mandatory impact indicators:

- Global warming potential (GWP, measured in kg CO2 equivalent)

- Depletion potential of the stratospheric ozone layer (ODP. measured in kg CFC11 equivalent)

- Acidification potential of soil and water sources (AP, measured in kg SO2 equivalent)

- Eutrophication potential (EP, measured in kg Ne)

- Photochemical smog creation potential (POCP, measured in kg O3 equivalent)

- Abiotic depletion potential (ADPfossil) for fossil resources (ADPf, measured in MJ or NCV)

- Fossil fuel depletion (FFD, measured in MJ Surplus)

GWP is significant as it is a direct measurement of embodied carbon and is the basic measurement of comparison within the EC3 tool.

Any given concrete product may have a wide range of GWP measurements. For example, a boxplot diagram of the GWP of 1,926 different concrete mixes designed to 6000 psi strength indicates a GWP range of 56.7 kg CO2 equivalent per cubic yard to 968 kg CO2 equivalent per cubic yard.

Simply by having this information available during product selection, a designer or builder can make an informed decision and make a significant difference to the net embodied carbon on a project.

4. Sourcing Data for EPDs

Sourcing the most up-to-date data sources for concrete EPDs can be a complex task. The world is changing so rapidly that it’s hard to ensure your EPD calculations have the most accurate data. Tools like EC3 can help, as can supply chain partners.

EPDs are the first step toward the level of transparency that supports sustainable design. By publishing this data, building product manufacturers are encouraged to take the next step: implementing solutions that reduce GWP to gain a competitive advantage when compared to other EPDs in the EC3 tool.

CarbonCure, for example, provides a 3-5% reduction in the GWP measurement displayed on an EPD. CarbonCure’s CO2 mineralization process is complementary to other GWP-reducing strategies such as using SCMs like fly ash and slag.

EPDs are not only good for customers, they’re a great way for concrete producers to differentiate their products. Producers who have taken efforts to reduce the carbon footprint of their concrete will now be well-positioned during the material selection process.

Download CarbonCure’s Impact on the GWP of Concrete or contact us directly for more information.